-

Sparck Technologies awarded Royal designation - March 27, 2025

-

OpenADR Alliance announces first OpenADR 3.0 certified products with EVoke Systems, E.ON Energy and Universal Devices - March 25, 2025

-

Growing fulfilment and contract packer appoints new Managing Director - March 25, 2025

-

When is it time to invest in a WMS? Understanding the key trigger points - March 25, 2025

-

eCapital helps Vantage Recruitment on its journey to financial success - March 24, 2025

-

Hugo Beck Celebrates 70 Years of Packaging Innovation with Open House Events - March 20, 2025

-

PROLOG FULFILMENT SUPPORTS LUNA DAILY’S COMMITMENT TO BETTER BODY CARE FOR ALL WOMEN - March 19, 2025

-

Motion Ventures launches largest-ever maritime tech fund at $100M to meet the industry’s new pace of adoption - March 18, 2025

-

ITD GLOBAL APPOINTS GROUP CHIEF REVENUE OFFICER - March 17, 2025

-

SURECAM TEAMS UP WITH ENTERPRISE FLEX-E-RENT FOR VEHICLE REPAIR & MAINTENANCE CONFERENCE - March 14, 2025

Edward Hutchison, Managing Director of BITO Storage Systems, highlights some of the important factors for procuring environmentally considerate materials handling equipment.

Products of any kind generally have a range of potential impacts on the environment and on human health. This can include ecosystem damage through overexploitation; pollution of soil, air and water; improper waste disposal; and toxic exposure of staff. Negative impacts can occur at any point during a product’s life cycle – from raw material extraction through to manufacturing, packaging, distribution, product use, repair, maintenance and disposal or recycling. By procuring environmentally considerate materials handling products, companies will contribute to sustainability of the environment and health across the value chain.

We know of course that an effective storage system will result in significant time and cost savings for a company. Through compact storage and clear product presentation, order throughput times can be reduced and logistics processes can be efficiently coordinated. This avoids downtime, increases warehouse productivity and reduces storage costs. But can sustainable procurement be applied to storage and materials handling equipment?

Yes it can. There are several key factors involved in maximising sustainability in materials handling. It starts with procuring raw materials and components that are not harmful to health and that allow for ‘greener’ processing. Preference should be given to manufacturers and suppliers who comply with ecological standards and consideration should be given to the distances materials need to travel to reach the production plants. BITO, for example, sources 90% of its materials for its products from within the EU market, helping customers and partners embrace sustainability in all areas of their business.

The uprights and beams of BITO’s steel shelving and racking are either galvanised or come in various colour options so the company opted for electrostatically applied powder coating instead of conventional liquid paint, which needs an evaporating solvent. Only colour pigments that are ecologically safe and release a very low amount of volatile organic compounds during the coating process are used. Typically, powder coatings are cured at temperatures of 140 – 200°C but BITO uses advanced low bake thermosetting powder that cross-links at temperatures of less than 140°C. Powder-coated work-pieces are extremely impact-resistant and weatherproof.

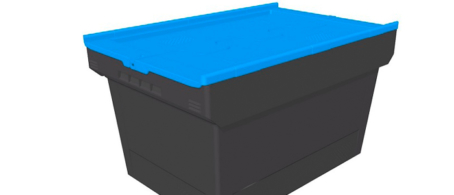

Another big factor in sustainable materials handling is the use of reusable packaging instead of disposable cardboard packaging, which will help reduce deforestation and its negative impact on the climate. During their long service life, BITO’s extremely durable multi-trip MB distribution plastic containers will each save more than 1 ton of cardboard. Sector specific variants include the MB Food & Delivery container, which has been designed for last-mile deliveries; and a MB for hazardous goods, which can be supplied with a drop-on lid complete with metal snap locks.

BITO’s bins and containers already contain 20% recycled material. Production surplus is regranulated in the company’s own recycling facility and returned 100% into the production cycle. On request, almost all bin and container series can be made from regranulate (post-process plastic).

Particularly sustainability-minded customers can also opt for the MB ECO distribution container made from certified post-consumer plastic derived from end products that have completed their lifecycle. This ecological alternative also offers an economic advantage, due to it being somewhat cheaper to manufacture and therefore has a lower selling price than the standard MB container. Although process engineering limits the ECO container’s body colour options to black, customers can still apply colour-coding by fitting lids in blue, yellow, green and red. The list of optional equipment, such as hinged lids or stacking rails, is the same as for the standard MB series.

These clever alternatives to one-way packaging will minimise impact on environment and resources. Plastic bins help speed up any company’s logistics processes, thereby raising productivity levels and saving money as well as natural resources.

The UK, which hosts the UN Climate Change Conference (COP26) in Glasgow between 1 and 12 November, has committed to a Net Zero carbon neutral target by 2050. Smart operators of warehousing, logistics and materials handling processes will be investing in solutions that will enable compliance with increasingly important sustainable requirements from clients and from government. Our advice is to discuss how sustainability in materials handling can be achieved with experts who can offer a full range of storage, logistics and materials handling products and systems.