-

Nutrivend selects Forterro’s Orderwise to support online expansion and streamline operations - April 11, 2025

-

ARROWXL LAUNCHES AMBITIOUS ZERO WASTE ROADMAP - April 8, 2025

-

THE BCMPA’S NEW CAMPAIGN DRIVES OUTSOURCING SUCCESS IN Q1 - April 7, 2025

-

BLACKOUT TECHNOLOGIES TARGETS TELEMATICS-INTEGRATED MOBILE DEVICE BLOCKING TO COMBAT SMARTPHONE DISTRACTION - April 1, 2025

-

Sparck Technologies awarded Royal designation - March 27, 2025

-

OpenADR Alliance announces first OpenADR 3.0 certified products with EVoke Systems, E.ON Energy and Universal Devices - March 25, 2025

-

Growing fulfilment and contract packer appoints new Managing Director - March 25, 2025

-

When is it time to invest in a WMS? Understanding the key trigger points - March 25, 2025

-

eCapital helps Vantage Recruitment on its journey to financial success - March 24, 2025

-

Hugo Beck Celebrates 70 Years of Packaging Innovation with Open House Events - March 20, 2025

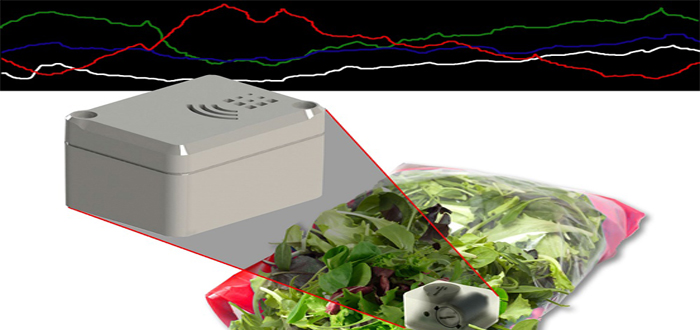

Real time environmental data collection from inside a food pack right across the distribution chain

EMCO Packaging has developed an advanced and highly sensitive data logger that collects environmental data actually from the inside a food pack. It measures oxygen content, temperature, relative humidity & pressure and operates from the time the food is packed on the production line right through storage, transport and even whilst it is on display in a frozen, chilled or normal cabinet.

The data logger can communicate wirelessly as well as storing up to 300,000 records in memory for later USB download.

By accurately monitoring the environmental conditions from inside the pack, the system provides the data necessary to analyse any changes, trends or conditions and optimise each part of the process – from the packaging materials themselves, through to storage, transport and display conditions. As a result produce can be delivered to the consumer in peak freshness and quality conditions.

Not only does the gas logger produce more accurate and realistic results throughout the supply chain than can be gained by ripping packs open at every stage of the process to take measurements – but it is far less destructive as well!

The data logger is just 65mm x 50mm x 37mm and is manufactured to a particularly high and rugged engineering standard. Oxygen and humidity are both measured to a resolution of 0.05% and 0.04% respectively, temperature to an accuracy resolution of 0.01% and pressure to a 16 bit resolution over a range of 10 – 1200mbar. www.emcopackaging.com