-

Nutrivend selects Forterro’s Orderwise to support online expansion and streamline operations - April 11, 2025

-

ARROWXL LAUNCHES AMBITIOUS ZERO WASTE ROADMAP - April 8, 2025

-

THE BCMPA’S NEW CAMPAIGN DRIVES OUTSOURCING SUCCESS IN Q1 - April 7, 2025

-

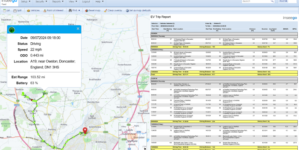

BLACKOUT TECHNOLOGIES TARGETS TELEMATICS-INTEGRATED MOBILE DEVICE BLOCKING TO COMBAT SMARTPHONE DISTRACTION - April 1, 2025

-

Sparck Technologies awarded Royal designation - March 27, 2025

-

OpenADR Alliance announces first OpenADR 3.0 certified products with EVoke Systems, E.ON Energy and Universal Devices - March 25, 2025

-

Growing fulfilment and contract packer appoints new Managing Director - March 25, 2025

-

When is it time to invest in a WMS? Understanding the key trigger points - March 25, 2025

-

eCapital helps Vantage Recruitment on its journey to financial success - March 24, 2025

-

Hugo Beck Celebrates 70 Years of Packaging Innovation with Open House Events - March 20, 2025

Single-source solution for conveying and processing alternative fuels

BEUMER provides Umweltdienste Bohn with single-source solution for conveying and processing alternative fuels:

An entirely closed system

In order to improve the efficiency of its operations, Deuna Zement GmbH, a subsidiary of Dyckerhoff, will use alternative fuels to fire the main burners of the two rotary furnaces in its plant in Deuna, a town situated in the German Free State of Thuringia.

Umweltdienste Bohn GmbH, based in Alsfeld, was commissioned to supply Deuna Zement with alternative fuels and will build a processing plant on Deuna’s premises as part of this partnership. As the general contractor, Umweltdienste Bohn engaged the BEUMER Group to provide a single-source solution for efficient conveying and feeding of the materials, which have different compositions. A Pipe Conveyor is at the core of the system. The enclosed system ensures environmentally safe, emission-free and low-energy transport of the material.

The scope of supply also includes three feeding hoppers with a screw conveyor, belt conveyor, rotary starscreens, scales, and in addition steel structure, electronics and controls. Commissioning is scheduled for February 2018.

“The client has opted for us because we supply the entire system from one source,” says Tomas Hrala, project manager at BEUMER Group. “Our know-how and our tailor-made systems permit us to offer optimum assistance.” Umweltdienste Bohn also gets comprehensive support from BEUMER, which can be contacted at all times.