-

Nutrivend selects Forterro’s Orderwise to support online expansion and streamline operations - April 11, 2025

-

ARROWXL LAUNCHES AMBITIOUS ZERO WASTE ROADMAP - April 8, 2025

-

THE BCMPA’S NEW CAMPAIGN DRIVES OUTSOURCING SUCCESS IN Q1 - April 7, 2025

-

BLACKOUT TECHNOLOGIES TARGETS TELEMATICS-INTEGRATED MOBILE DEVICE BLOCKING TO COMBAT SMARTPHONE DISTRACTION - April 1, 2025

-

Sparck Technologies awarded Royal designation - March 27, 2025

-

OpenADR Alliance announces first OpenADR 3.0 certified products with EVoke Systems, E.ON Energy and Universal Devices - March 25, 2025

-

Growing fulfilment and contract packer appoints new Managing Director - March 25, 2025

-

When is it time to invest in a WMS? Understanding the key trigger points - March 25, 2025

-

eCapital helps Vantage Recruitment on its journey to financial success - March 24, 2025

-

Hugo Beck Celebrates 70 Years of Packaging Innovation with Open House Events - March 20, 2025

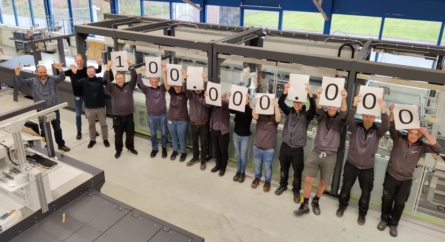

Sparck Technologies, the new name for Packaging by Quadient, has hit a major milestone with 100 million boxes produced on its revolutionary fit-to-size packaging machines worldwide. As Sparck’s advanced CVP Everest and CVP Impack packaging systems make each cardboard box to the exact size required for every particular order, the company calculates that some 34,250,000 sq m of cardboard has been saved through the use of its technology, equating to the preservation of 46,000 trees.

In addition to the material savings and ecological benefits, the effect of the total volume reduction resulting from fit-to-size packaging across 100 million packages is estimated to have removed 31,700 lorry loads from the roads, contributing to reductions in the carbon footprint of Sparck Technologies’ customers worldwide.

Jo Bradley, Business Development Manager, Sparck Technologies, says: “Hitting this key milestone of one hundred million boxes really brings home the growing pace of adoption of right-size packaging technology and the important role it is playing in making ecommerce more sustainable. Our calculations relating to the significant total savings in resources and transport that have been achieved, gives some idea of the collective, positive impact individual companies can make by using available technology to right-size their packaging. Given that the collective gains are clearly so significant, imagine what could be achieved through industry wide adoption.”

With the capability to tailor-make up to 1,100 packages per hour, for multiple or single items, the CVP Everest and CVP Impack Packaging Systems offer automated solutions for e-commerce operations challenged by increasing order volumes, labour shortages and rising shipping costs. With installations in more than 13 countries, the CVP Automated Packaging Solutions effortlessly create, fill, fold and label each parcel in one seamless process – reducing package volumes by up to 50%, cutting cardboard usage by 30% and eliminating the need for void fill.

Come and see the latest in perfect-sized packaging on the Sparck Technologies stand (500) at IntraLogisteX 2022, 29th & 30th March, CBS Arena, Coventry.